Ecoservice, a Lithuanian company owned by Eco Baltia, sues Compensa for more than a year’s delay in paying compensation

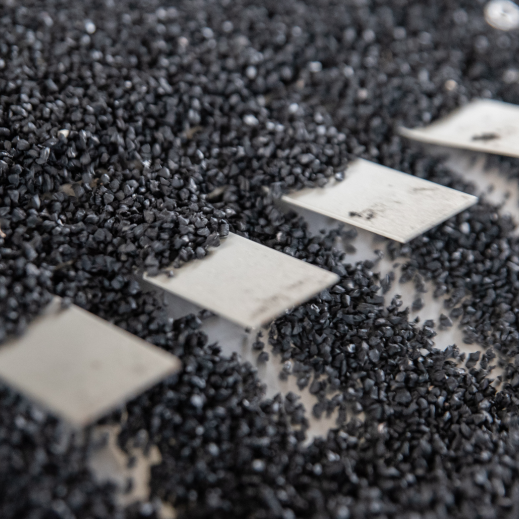

Ecoservice, the Lithuanian environmental services company of Eco Baltia, the largest environmental resource management and recycling group in the Baltics has brought an action before the Riga City court demanding the insurance company Compensa Vienna Insurance Group ADB, Latvian branch, to fulfil its obligations and to pay out the insurance indemnity for the damage suffered by Ecoservice as a result of a fire. The fire that broke out on 5 August 2023 in the company’s waste sorting centre caused widespread damage, destroying the buildings, the waste sorting equipment and part of the inventory.

Ecoservice’s application submitted to the court states that the Latvian branch of Compensa unreasonably delays the decision on the insurance claim. More than a year after the accident, the insurance company not only does not take a decision on whether the accident should be declared insured, but also does not take a decision on whether to pay the full or partial indemnity.

In this claim, Ecoservice seeks a payment of €7.4 million in insurance indemnity and interest for late payment. The company is also finalising the calculation of the losses it suffered when it had to partially suspend its operations after the fire. This amount will be added to the claim when it becomes clear. This could increase the claimed amount to more than €10 million.

Compensa’s conclusions are not forthcoming

“The fire happened last year, but Compensa has not yet decided whether to recognise it as an insured event, even though the Department of Environmental Protection and the Department of Fire Protection and Rescue carried out investigations and established the essential circumstances, so the situation is more than clear. Despite our sorting centre being insured, Compensa’s unreasonable delays have prevented us from restoring our previous operational capacity. This creates serious challenges because, despite the insurer’s refusal to pay the insurance indemnity, our waste management obligations remained the same after the fire. We must fulfil our obligations, otherwise there could be serious environmental consequences”, comments Jurgita Nacevičienė, Manager of Ecoservice.

According to her, the company is currently forced to rebuild capacity with its own funds. This makes it more difficult to operate and hampers development, as it has to redirect part of its own working capital, as well as money planned for strategic business development projects. It is estimated that the ongoing reconstruction of the sorting centre will require a total of EUR 18 million.

Māris Simanovičs, chairman of the board of AS “Eco Baltia”, points out that the stability of the company is based on timely decision-making: “Any changes can have a significant impact on the future development of the company, especially when it comes to restoring operations after an accident. In view of this, we take the firm decision to insure such risks in advance and expect insurers to honour their commitments. This was highlighted by the summer storms and subsequent floods which affected many people and businesses. Insurers must fulfil their obligations within the legal framework by paying compensation without undue delay, regardless of the amount.”

A pre-trial investigation is ongoing

After the fire, Ecoservice found the right solutions and was able to quickly restore its operations. This led to a significant reduction in the fire loss and thus in the final insurance indemnity amount, as the company had also insured for business interruption.

According to Nacevičienė, Ecoservice ensured close cooperation with the insurer from the very first days of the fire, and all the necessary materials available to the company were promptly provided to the insurer. Compensa seems to be intentionally dragging out the process by quoting aspects with little relevance for the insurance case as an excuse not to adopt the decision on whether Ecoservice is entitled to receive the insurance indemnity.

First, the insurer questioned the legality of the awning hangar, even though it had insured the hangar and received the insurance premium payment for it. Then, the insurer mentioned potential nonconformities regarding the height of the waste pile in the yard and the amount of waste stored there, although the competent authorities have expressly stated that no violations were found.

After, it was an excuse about inability to adopt decision while a pre-trial criminal investigation related to the fire is not concluded, although it has a completely different scope and targets.

Ecoservice has been waiting for more than a year for a decision from the insurer and cannot delay any longer. Especially since meetings with the insurer’s representatives no longer allow for positive and constructive cooperation with Compensa.

As the insurance contract was concluded with Compensa’s branch in Latvia, after reaching an impasse in the negotiations with the insurer, Ecoservice filed the claim to the Riga City Court.

Vytautas Plunksnis

Vytautas Plunksnis  Deimantė Korsakaitė

Deimantė Korsakaitė  Alberto Atienza Güell

Alberto Atienza Güell  Jurgita Petrauskienė

Jurgita Petrauskienė  Gints Pucēns

Gints Pucēns  Algimantas Markauskas

Algimantas Markauskas  Māris Simanovičs

Māris Simanovičs  Santa Spūle

Santa Spūle  Sigita Namatēva

Sigita Namatēva  Saulius Budrevičius

Saulius Budrevičius