Eco Baltia continues to grow turnover this year – up 10% in the first quarter

The largest environmental resource management and waste recycling group in the Baltics, Eco Baltia JSC (AS), has closed the first quarter of 2024 with a net turnover of EUR 61.9 million, up 10% year-on-year (Q1 2023: EUR 56.3 million). The turnover was mainly driven by a solid and convincing performance in the environmental management sector, focused efforts on efficiency and automation, and business expansion through acquisitions.

The Group’s consolidated profit before tax for the first three months of 2024 was EUR 670.9 thousand, while consolidated EBITDA in the first quarter reached EUR 9.1 million, an increase of 10.4% compared to the same period last year.

Māris Simanovičs, Chairman of the Management Board of Eco Baltia: “This year we continue to increase the pace of development of the company, focusing on productivity, as well as new businesses and markets. Last year, we already achieved historically unprecedented results, thus strengthening our position in the Latvian and international markets. Similarly to last year, in the first months of this year we have continued to evaluate the development of the Group through the acquisition of new businesses. We are also continuing to work on a number of investment projects in Lithuania and Latvia, which will allow us to increase both the amount of waste collected and the amount of waste recycled over the next few years.”

Expanding Eco Baltia’s portfolio of companies and services, an agreement was signed in March this year to acquire 100% of the shares in Eko Osta, a Latvian company that manages environmentally harmful and hazardous waste. The transaction will continue after the merger has been approved by the Competition Council. Also at the beginning of this year, Eco Baltia acquired a 40.4% stake in the Latvian road maintenance company JSC (AS) Daugavpils specializētais autotransporta uzņēmums.

Eco Balta Group’s largest environmental management companies – Eco Baltia vide in Latvia and Ecoservice in Lithuania – continued to develop a number of investment projects in the first quarter of the year. Eco Baltia vide invested EUR 2.3 million in the construction of construction waste sorting and recycling sites in the Baltic Sea region (Rumbula) and Liepāja. Both sites have gradually started operations in early summer. Eco Baltia vide is also continuing work on the establishment of a sorting plant for municipal and separately collected waste in Acone, Pierīga, which started last year with a total investment of €11.7 million and will be able to sort 45 000 tonnes of waste annually. Meanwhile, the Lithuanian environmental management company Ecoservice approved an investment of €18 million in early 2024 to rebuild a waste sorting centre in Vilnius, which was hit by fire last year.

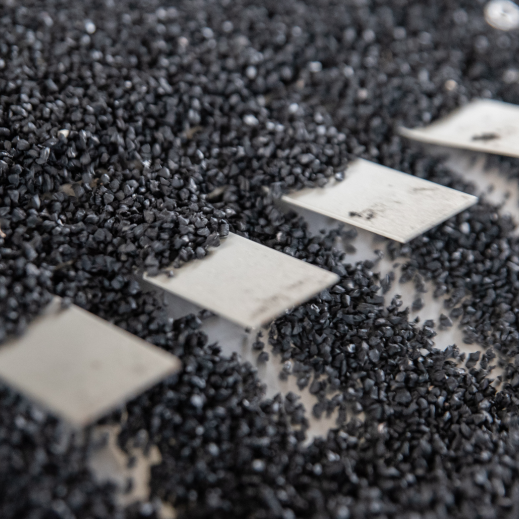

Targeted development was also implemented in the recycling sector, where PET Baltija, a PET bottle recycler, completed a rebranding and name change to ITERUM this summer. During the first quarter, work continued on the new PET bottle recycling plant in Olaine, with a total project investment of more than €35 million. More than €10 million of this was contributed by ITERUM. The building will have a total area of approximately 26,250 m2 and will be one of the largest industrial buildings in Latvia and one of the largest PET recycling plants in Northern Europe. At the same time, ITERUM continues to promote the sale and production of products in cooperation with its Czech subsidiary Tesil Fibres, a leading supplier of fibres to the European market for the automotive, hygiene, textile and furniture segments, by developing the recycled PET raw material chain.

Despite the challenges in the recycling sector in recent years, we have used this period to improve efficiency and automate production processes, which is an integral part of long-term business development in the current market conditions. In the coming years, this will allow us to sort waste more accurately, improve the quality of recycled materials, increase recycling capacity and thus bring more waste back into the circular economy. At the same time, we place a strong emphasis on the well-being of our employees. Therefore, we always set high standards in terms of improving the internal work environment and work safety, developing the skills of employees, as well as creating a family-friendly work environment,” says Mr Simanovičs.

As the Eco Baltia Group’s business model and operations are focused on the circular economy, the development and implementation of a consolidated ESG (Environmental, Social and Governance) strategy is also being pursued in the Group’s companies. In line with the Group’s strategic objectives, the main focus in 2024 will be on improving working conditions and safety, the well-being of employees and the promotion of ESG and sustainability.

Vytautas Plunksnis

Vytautas Plunksnis  Deimantė Korsakaitė

Deimantė Korsakaitė  Alberto Atienza Güell

Alberto Atienza Güell  Jurgita Petrauskienė

Jurgita Petrauskienė  Gints Pucēns

Gints Pucēns  Algimantas Markauskas

Algimantas Markauskas  Māris Simanovičs

Māris Simanovičs  Santa Spūle

Santa Spūle  Sigita Namatēva

Sigita Namatēva  Saulius Budrevičius

Saulius Budrevičius