June 12, 2013 the full-cycle waste management and recycling joint stock company Eco Baltia opened the only high-quality PET pellet mill Eko PET at the Jelgava Business Park. The project of the mill was developed with the financial support of the Investment and Development Agency of Latvia and received LVL 3.7 million in investments. The new Eko PET mill is the most technically complex and modern plastic waste recycling factory in the Baltic States.

The annual output capacity of Eko PET is 8.5 thousand tons of PET pellets. This is the amount of raw material needed for the production of 270 million PET bottles, which exceeds the 160 million of PET bottles discarded in Latvia every year. Consequently the amount of pellets produced by Eko PET provides for both the Latvian and Estonian markets thus also making it the largest mill of this type in the Baltic States. The main cooperation partner and the supplier of PET pellets for Eko PET is the company’s co-owner joint stock company PET Baltija – the biggest PET waste management company in the Baltic States with a ten years’ experience in the market.

Artūrs Skroderis, Eco Baltia group board chairman: “The new Eco PET mill is an acknowledgement that by using modern technologies, a local company is capable of creating a plant with high value added. The resources of PET Baltija and Eko PET will allow for the recycling of PET bottles from all three Baltic States. This is a significant advantage in comparison to our neighbouring countries. The aim of the new mill is to provide raw material (PET pellets) for the production of new bottles not only to the Baltic region but also to compete in the international market. This will allow for the discontinuation of the use of non-renewable resources – crude oil products, and produce PET bottles from recycled materials.”

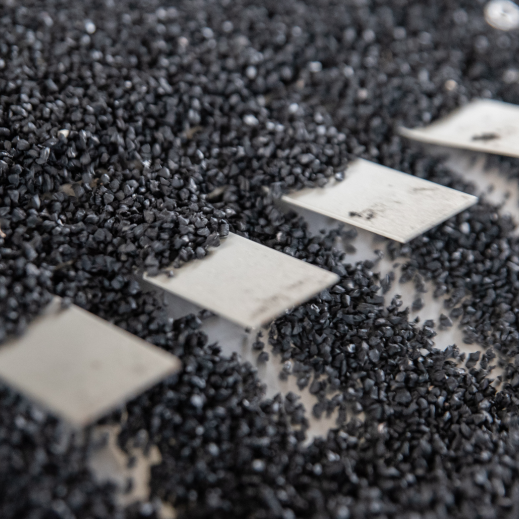

The company will produce pure recycled plastic or PET pellets with high value added from hot washed PET flakes. PET flakes are produced by recycling waste PET packaging collected in Latvia and other European countries. PET pellets is a secondary raw material used for the production of food packaging and is an alternative to the packaging produced from crude oil products. Recycled PET pellets may be used to produce food packaging, such as new PET bottles or film. The Eko PET mill has been installed with the PET plastic recycling machinery solutions by the leading Austrian machinery and process technology company Starlinger Group.

Andris Rāviņš, Mayor of Jelgava: “Jelgava has always preserved its traditions of production and productive environment for new businesses. The new mill confirms this – Eko PET is a significant contribution to the development and economic growth of the city thus developing it into a modern centre of entrepreneurship and industry. Furthermore every new business started in Jelgava means new jobs for the town. It also affirms the town’s high potential for new investments.” A strict internal quality control will be implemented during the production process which is the main precondition for the production of food grade PET pellets. The mill was launched in test mode on April 10 this year. The company has been certified by the Food and Drug Association (FDA) and the International Life Sciences Institute (ILSI). The company is preparing to implement a quality system according to ISO:9001, ISO:14001 and ISO:18001 standards.

Vytautas Plunksnis

Vytautas Plunksnis  Deimantė Korsakaitė

Deimantė Korsakaitė  Alberto Atienza Güell

Alberto Atienza Güell  Jurgita Petrauskienė

Jurgita Petrauskienė  Gints Pucēns

Gints Pucēns  Algimantas Markauskas

Algimantas Markauskas  Māris Simanovičs

Māris Simanovičs  Santa Spūle

Santa Spūle  Sigita Namatēva

Sigita Namatēva  Saulius Budrevičius

Saulius Budrevičius