According to the unaudited consolidated annual report, the largest environmental management and recycling group in the Baltics, AS Eco Baltia, in 2022 achieved record-high consolidated net turnover to date, reaching €210.79mn. This represents a 75.7% increase compared to 2021, when consolidated net turnover was €120.0mn. Eco Baltia’s pro-forma revenues (which account for the full-year effect of the newly acquired companies within the financial year) reached €240mn, growing by 60% compared to €150.0mn pro-forma revenue in 2021. Growth in revenues is attributed to a combination of factors, including the acquisitions of Ecoservice in 2021 and TESIL Fibres in September 2022, favorable market conditions for PET and plastic recycling business segments in first half of 2022, stable and growing business in the environmental management segment and focus on productivity and efficiency.

In 2022, Group’s consolidated net profit was €7,31mn. Net profit in 2021 was €9,33mn. In reporting period consolidated EBITDA reached €25,47mn in comparison of €19,9mn in 2021.

Māris Simanovičs, Chairman of the Board at Eco Baltia, commented: “Despite the challenging geopolitical landscape that has impacted businesses worldwide, we achieved record-breaking results in 2022 with a consolidated revenue of €210,79mn and pro-forma revenue of €240mn. This dynamic growth was driven by our strategically implemented M&A deals, as well as strong performance in environmental management, PET and plastics recycling. Our dedication to the circular economy, productivity, and efficiency enabled us to navigate the challenges of the global and local business sentiment and rapid growth of production costs. In 2023, we will keep our commitment to invest in further development – both through M&A deals and capital investments in productivity, sustainability, and production capacity.”

In 2022, Eco Baltia’s companies in both business segments – PET and plastic recycling and environmental services – continued dynamic and vertically integrated growth in accordance with the long-term strategy. During the reporting period, Eco Baltia subsidiaries concluded several acquisitions to strengthen their positions in the international market and to expand services offered by the group’s companies. In 2022, Eco Baltia’s PET and plastic recycling segment companies generated €99,58mn consolidated net revenues, while environmental segment €111,21mn.

In September 2022, Eco Baltia’s subsidiary PET Baltija completed the acquisition of 100% of shares of a leading Czech polyester fiber producer, TESIL Fibres. Also, in September 2022, Eco Baltia’s environmental management company in Lithuania, Ecoservice, acquired 100% of shares of the liquid waste management company Mano Aplinka plius UAB. In January 2023, Latvian Eco Baltia vide completed the acquisition of the road and street maintenance company Pilsētas Eko Serviss.

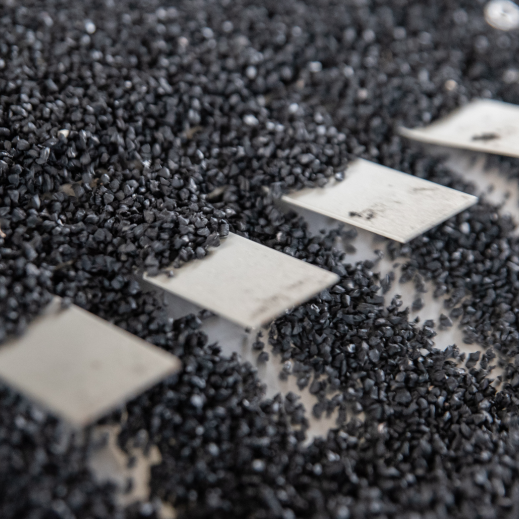

PET Baltija continued its investments in production expansion set to more than triple the existing food-grade rPET capacities. Its new factory in Latvia, Olaine, is now under construction, and production is planned to gradually start in 2023. The plastic packaging recycling company Nordic Plast also continued organic growth in the reporting period, supported by investment in production capacity. In the beginning of 2023, Nordic Plast with €2.8mn investment completed the modernization project (installed new automated sorting line) to increase production capacity up to 29%.

In 2022, Eco Baltia’s environmental management segment demonstrated stable growth, expanding the business portfolio and services provided by the group’s companies. In the reporting period, Eco Baltia launched and introduced a new service to the market – portable toilets branded as Tōcha. Both in Latvia and Lithuania, the environmental management companies continued to invest in construction debris sorting and management fields. Ecoservice made around €0.7mn investments to broaden and improve the existing construction debris sorting field, while Eco Baltia started construction of a new site.

Considering the high inflation and energy costs in Latvia, to support and help employees during the heating season, when living costs increase significantly, Eco Baltia and its subsidiaries in Latvia introduced a special support program for employees in December 2022. The support program included financial support for all Latvia employees (~900) for three months (Dec 2022 – Feb 2023). Each employee received a total of 300 EUR (before tax), and the total investment in this program reached ~EUR 330,000.

In 2023 investments in the PET and plastics recycling sector and environmental management will be continued, to support further growth, efficiency and competitiveness of the Group’s companies. In 2023 its planned to gradually start production in the new factory of PET Baltija in Olaine. Company’s investment in the new equipment for the new facility will totally reach over 10 million euro.

In the end of 2022, Group has decided to develop a new waste sorting plant in Latvia, in the region of Pierīga. The project will be implemented by its subsidiary in Latvia, Eco Baltia vide. The total investment in the project will amount to approximately 11 million euros, with more than half of the funds intended for the purchase of equipment. Contracts with suppliers have already been concluded. It is planned that the plant will commence operations in the first half of 2024.

Improving working conditions, supporting its employees, ensuring the highest level of labor safety, and improving ESG and sustainability are among the group’s priorities in 2023. The Eco Baltia group, providing a complete waste management cycle, is already a climate-neutral company, meaning that its operations are able to compensate for the CO2 emissions it produces. However, to strengthen this position, one of the goals for 2023 is also to renew the Eco Baltia Sustainability Strategy in line with the United Nations Sustainable Development Goals and the goal of climate neutrality. Eco Baltia and its subsidiaries are working towards resource-efficient consumption, promoting circular economy, transitioning to more environmentally friendly transportation in waste management, increasing the proportion of recycled materials in production, reducing CO2 emissions, improving working environment and employee well-being, as well as introduce social initiatives that promote public awareness of responsible resource consumption and the need for waste sorting.

Vytautas Plunksnis

Vytautas Plunksnis  Deimantė Korsakaitė

Deimantė Korsakaitė  Alberto Atienza Güell

Alberto Atienza Güell  Jurgita Petrauskienė

Jurgita Petrauskienė  Gints Pucēns

Gints Pucēns  Algimantas Markauskas

Algimantas Markauskas  Māris Simanovičs

Māris Simanovičs  Santa Spūle

Santa Spūle  Sigita Namatēva

Sigita Namatēva  Saulius Budrevičius

Saulius Budrevičius